Sensors integration for a new methodology in ultrasounds-based plastic injection

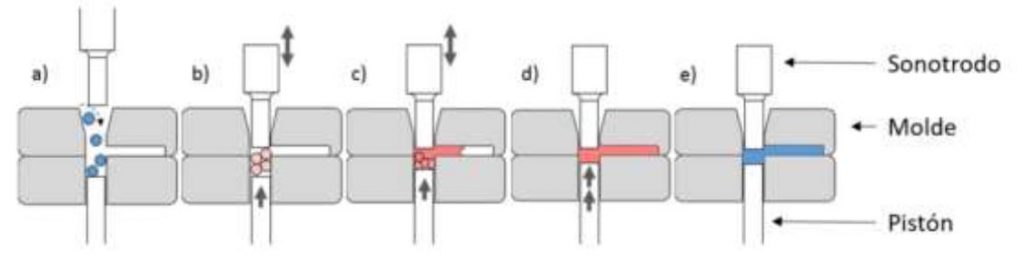

At the present time, ULTRASION is the only company offering a plastic injection machine based on Ultrasounds Molding Technology (USM). This technology, though very disruptive and adding benefits to conventional injection, has only been used effectively in R+D environments due to its insufficient repeatability.

ULTRASION is now preparing the second generation of its machines, focused on production at an industrial scale. In this context, the increase of repeatability and ease of use is one of the challenges towards guaranteeing the correct industrialization of the new model. Our main development line is the digitalization of the process by means of:

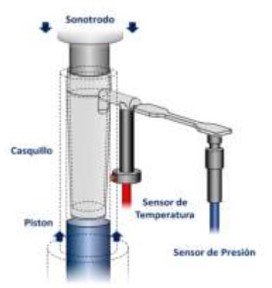

- Sensorization of the process with new pressure and temperature sensors integrated in key locations of the mold.

- The feedback of acquired data, so that the process adapts in real time to sudden deviations of critical magnitudes.

- The application of AI algorithms, which will make decisions based on sensor data, goal results, past results, material properties, mold geometry, etc.

The satisfactory conclusion of these tasks will allow ULTRASION to make the USM process more stable, and reduce the amount of time needed to test new materials and geometries.

General data

Project

Sensors integration for a new methodology in ultrasounds-based plastic injection

Program and edition

Cupó d’Assessorament en la Implantació Indústria 4.0 – 2021 Edition